PhenolicBacked Wood Veneer WaterResistant Paneling

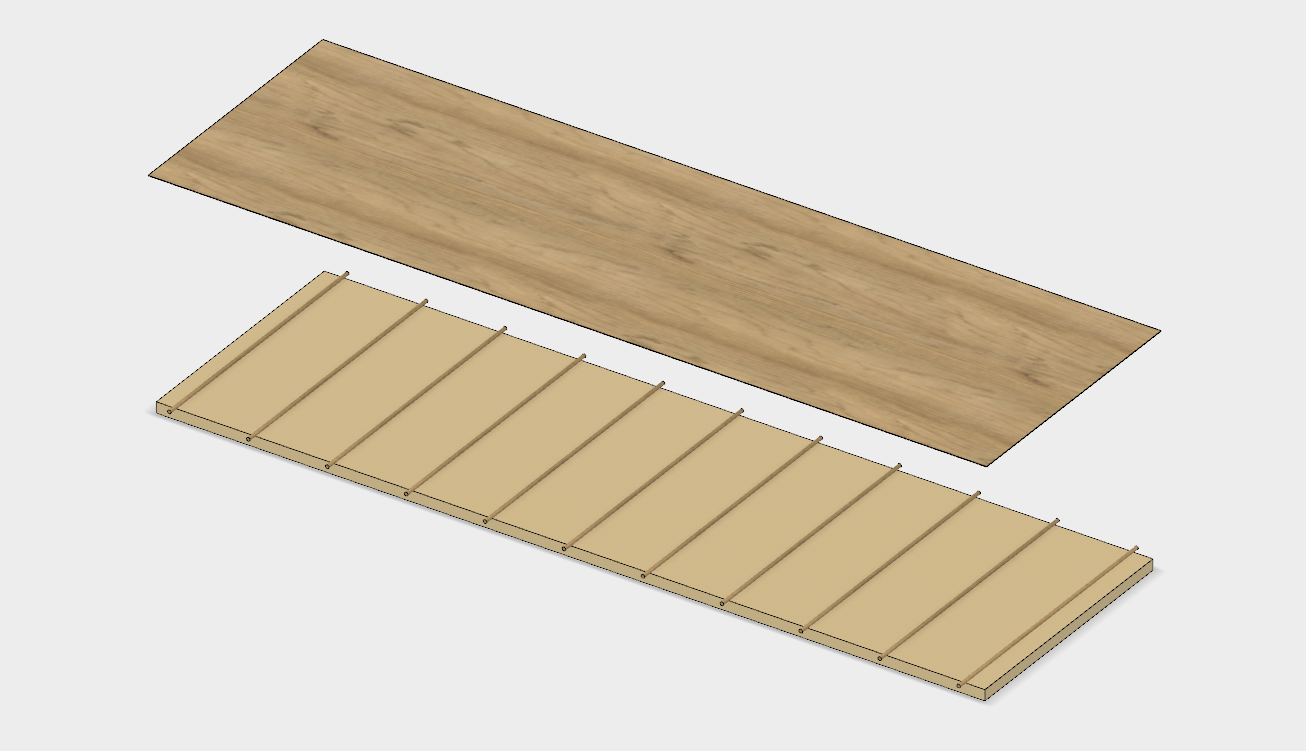

When the moisture content of the veneer changes, it will place stress on the substrate. By balancing the panel with a veneer on the back side, those stresses are kept even and the panel will stay flat. When to Apply a Balance Veneer. A balance veneer can be applied immediately after the face veneer comes out of the press.

Wood Veneer with Peel & Stick Wood Back WalzCraft

Decoflex are flexible wood veneer sheets, obtained by first pressing real wood veneer on a paper backing and subsequently breaking the wood fibres. The surface is sanded with a 150 grain sandpaper and is ready for use. Decoflex can be laminated easily and is perfect for use in production of doors and other furniture components. In Europe, the.

Fleece backing machine for veneer by Duespohl

Wood Veneer UK specialise in supplying you with a choice of the world's finest quality wood veneers by Mail Order. We offer a wide range of Marquetry Supplies, Paper Backed Wood Veneers, decorative veneers and exotic wood veneer species. All our veneers can be purchased as single wood veneer sheets for your convenience, and are ideal for.

NonAdhesive Resin Back Veneer WalzCraft

Long Grain Paper-backed Veneer (2440 x 1220 x 0.8mm) Login to See Prices. Please phone 0161 8346789 or 07540121601 for a price Due To current market conditions. Please find our applications recommendations for this flexible paper backed veneer application product. A paper backed veneer is a piece of sliced wood from a wooden log permanently.

Veneer with 10 Mil Paper Backing, 1' x 8' Roll Rockler Woodworking

Paper Backed Wood Veneer. Decoflex Paper Backed Veneer is an innovative veneer product using the latest in technology with natural veneer to create a easy-to-use, flexible veneer sheet. All of our Decoflex sheets are sized at 244cm x 122cm ( 96" x 48" ) and the overall thickness of Decoflex is between 0.4mm and 0.6mm.

Backing Timber Veneer (Lauan) BV02A12 Australian Premier Veneers

We are always happy to help. Veneer jointing or stitching is the process of joining veneer leaves together to form a fixed-length sheet of veneer known as a layon, sometimes also known as skins or faces. As the name describes, the layons can then be laid onto a substrate to create a veneered board which can be used for doors, furniture.

rotary cut okoume veneer backing veneer Natural Veneer Rotary Cut

Wood Veneer Description The Cedar of Lebanon veneer dates back to ancient times where it was used to build some of the most historic buildings know. View full details Original price £11.25 - Original price £17.25 Original price. £11.25 - £17.25. £11.25.

Natural red oak veneers with fleece backing Red oak, Wood veneer, Veneers

The HPLT pressing process (High Pressure Low Temperature) that Decospan applies guarantees the highest quality for each type of panel. This unique method is the result of our decades of experience in pressing methods and veneer processing. When ordering a veneered panel, it is essential to select the right base board and the right backing.

Before And After Laminate Veneers Before And After

Paper Backed Wood Veneer is an innovative veneer product using the latest in technology with natural veneer to cr. View full details Original price £34.99 - Original price £89.99 Original price. £34.99 - £89.99. £34.99 - £89.99. Current price £34.99 Choose options.

Technical Specification of chevron Veneers Natural Veneers

Paper & Backing Veneer. As veneer is usually approximately 0.6mm thick it is fragile. To ensure the veneer's stability it needs to be pressed onto a substrate such as MDF, chipboard or plywood. Substrates will warp if you only veneer one side thus the need for a backing. The backing is also known as a "balancer" or "compensator". We.

Backing Veneer (Coachwood) BV07A12 Australian Premier Veneers

Center the selected pattern section over the substrate panel and apply the contact cement, following the manufacturer's instructions, to both the veneer and the substrate. Allow it to set. Be sure to mix the adhesive thoroughly before applying it. This will maximize its effectiveness.

Fleece Backed Veneer How to Make Fleece Backed Veneer Sheets and

A backed veneer won't need to be flattened; it's ready to apply immediately. Always cut your veneer slightly larger than the substrate. You'll trim it to size after it's applied. For a 25-1/2" x 84" countertop, you might want to cut your veneer to 26-1/2" x 85.". Apply a thin, even coat of contact adhesive to the backing and the.

Paper Backed Veneer Sheets YouTube

For paper-backed veneer Test the back of the paper backed veneer by applying a single drop of water to the backing. If there is still a bead of water after 5 seconds, then the backer is creating the problem with the adhesion. The solution is to scuff sand the backer with 80 or 100 grit sand paper.

Woodwork Adhesive Wood Veneer PDF Plans

Complete your free online smile assessment and find the instasmile that's right for you. Get 30% Off Plus Free Extras Worth £250 - Use Code HAPPY30

How to Apply Wood Veneer with Backing Popular Woodworking

Engineered wood veneers are sliced from softer, rapidly growing renewable species. The veneer is dyed in vats, dried and glued together into various shaped blocks where it will be re-sliced and re-glued, depending on the desired pattern. The finished product can emulate natural wood features like a crown, quarter and straight grain.

Veneer with 10 Mil Paper Backing, 1' x 8' Roll Rockler Woodworking

The veneer has a 0.010" paper backing. I measured the total thickness to be 0.025", so that leaves a thin 0.015" for the wood itself. Not much room for sanding mistakes! If you haven't used veneer before, cut a small 6" square piece from the roll and practice the steps below on a piece of scrap MDF or plywood. I actually made two test samples.